Inertial Measurement Unit (IMU)

An Inertial Measurement Unit (IMU) is a critical sensor in FRC robotics that measures a robot's orientation, angular velocity, and linear acceleration. IMUs enable autonomous navigation, field-oriented drive systems, and precise robot positioning.

What is an IMU?

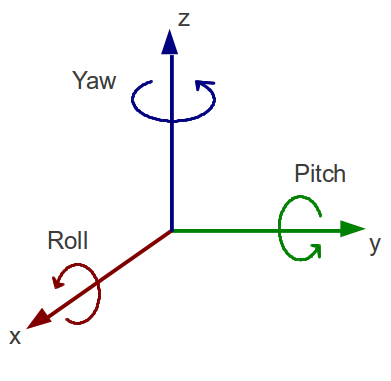

An IMU typically combines several sensors:

- Gyroscope: Measures angular velocity (rotation rate) around three axes

- Accelerometer: Measures linear acceleration along three axes

- Magnetometer: Measures magnetic field strength (compass functionality)

Together, these sensors provide 9 degrees of freedom (9-DOF) of motion data, allowing you to determine your robot's orientation in 3D space. The most important measurements are typically from the gyroscope (heading/yaw) and accelerometer (pitch and roll).

CTRE Pigeon 2.0

Key Features:

- 9-axis fusion algorithm for precise heading calculation

- CAN bus communication for reduced wiring

- Temperature compensation for improved accuracy

- Built-in vibration rejection

- Easy integration with Phoenix framework

Wiring:

CAN High (Yellow) → CAN Bus High

CAN Low (Green) → CAN Bus Low

V+ (Red) → 12V

GND (Black) → Ground

CTRE Docs:

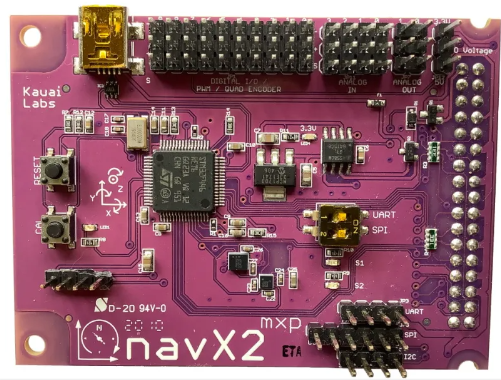

Kauai Labs (Studica Robotics) NavX-MXP

Key Features:

- 200Hz update rate for responsive control

- Multiple connection interfaces (SPI, I2C, USB, Serial)

- Built-in sensor fusion algorithms

- Collision detection capabilities

- Comprehensive software libraries

Wiring (SPI Connection - Recommended): Connect to the MXP port on the roboRIO:

MXP Pin 1 → 3.3V

MXP Pin 2 → DIO 0 (CS)

MXP Pin 4 → DIO 1 (MISO)

MXP Pin 6 → DIO 2 (MOSI)

MXP Pin 8 → DIO 3 (SCLK)

MXP Pin 14 → Ground

Studica Docs:

FRC Applications

1. Field-Oriented Drive

IMUs enable field-oriented (field-centric) drive systems where robot movement is relative to the field rather than the robot's orientation.

public void fieldOrientedDrive(double xSpeed, double ySpeed, double rotation) {

// Get current robot heading

double robotAngle = Math.toRadians(imu.getHeading());

// Transform driver inputs to field-relative coordinates

double fieldRelativeXSpeed = xSpeed * Math.cos(robotAngle) + ySpeed * Math.sin(robotAngle);

double fieldRelativeYSpeed = -xSpeed * Math.sin(robotAngle) + ySpeed * Math.cos(robotAngle);

// Drive the robot

drivetrain.drive(fieldRelativeXSpeed, fieldRelativeYSpeed, rotation);

}

2. Autonomous Navigation

IMUs provide critical heading information for autonomous routines:

public class TurnToAngleCommand extends CommandBase {

private final DriveSubsystem drivetrain;

private final double targetAngle;

private final PIDController turnController = new PIDController(0.02, 0, 0.004);

public TurnToAngleCommand(DriveSubsystem drivetrain, double targetAngle) {

this.drivetrain = drivetrain;

this.targetAngle = targetAngle;

addRequirements(drivetrain);

turnController.setTolerance(2.0); // 2 degree tolerance

turnController.enableContinuousInput(-180, 180);

}

@Override

public void execute() {

double currentAngle = drivetrain.getHeading();

double turnSpeed = turnController.calculate(currentAngle, targetAngle);

drivetrain.arcadeDrive(0, turnSpeed);

}

@Override

public boolean isFinished() {

return turnController.atSetpoint();

}

}

3. Balance Detection

Use IMU pitch readings to detect when your robot is on the charging station (2023):

public boolean isOnChargingStation() {

double pitch = Math.abs(imu.getPitch());

return pitch > 10.0; // Robot is tilted more than 10 degrees

}

public boolean isBalanced() {

double pitch = Math.abs(imu.getPitch());

return pitch < 2.5; // Robot is within 2.5 degrees of level

}

Troubleshooting

- IMU not detected: Check wiring and CAN/SPI connections

- Inconsistent readings: Ensure proper mounting and calibration

- Drift over time: Implement periodic resets and consider environmental factors

- Noisy data: Add software filtering or check for mechanical vibration